伽马射线辐照器由钴-60

(一种能够产生伽马辐照的同位素)提供能量。 伽马射线辐照是一种电磁能,具有穿透力强的特点,能够有效杀灭产品及包装内外的微生物,而且温度影响非常小,无残留。

请联系我们,启动您的项目

联系我们

伽马射线辐照在处理多种医疗器械、药品、食品和商业产品以及改善很多不同类型材料的性能方面非常有效。

以数十年的成熟科学、技术和标准为后盾,用钴-60 进行伽马射线灭菌可确保安全性、可靠性和有效性。

关于超高的精准度和可重复性,请了解我们的以下服务:

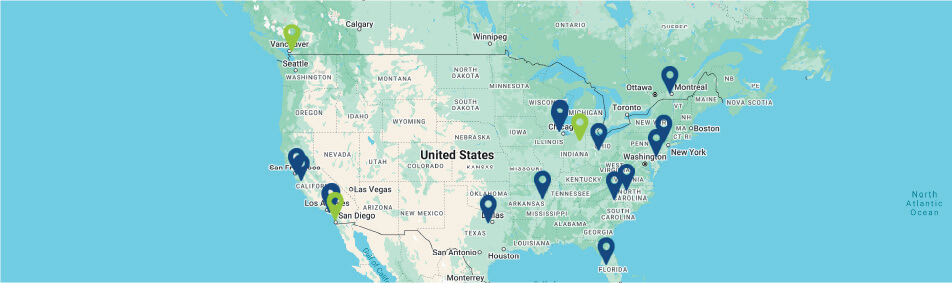

凭借庞大的全球网络和数十年的行业专业知识,伽马射线辐照仍然是一次性医疗器械、药品、食品和其他产品的理想灭菌技术。

基于行业悠久历史建立的包含近 300 家伽马射线辐照工厂的网络为依赖关键灭菌步骤的供应链提供了强大的产能,帮助确保面向患者和医疗保健提供者的产品的安全性。

自 2015 年以来,已有 20 多家辐照工厂在 10 个国家/地区落地。 我们的兄弟企业 Nordion 拥有 70 多年的历史,是领先的钴-60 供应商。随着伽马射线产能和需求的持续增长,该公司参与了一系列正在实施的项目,以建造更多工厂。

钴-60 具有较高的密度,使得这种放射性同位素能够在该领域保持近 20 年的活跃使用。 通过回收计划,超过 99% 的这种材料将从该领域返回到新的来源。 运输产生的碳足迹很小,可在产品的整个生命周期中摊销。

与其他工业灭菌技术相比,伽马射线灭菌具有显著的环境优势。 X 射线工厂通常会消耗大量电力,这些电力往往通过不可再生技术产生。与 X 射线工厂相比,使用钴-60 作为电离辐射源可减少 15 倍的电力消耗和 12 倍的温室气体排放。

我们是全球领先的面向医疗器械、制药、食品安全和先进应用市场的外包终端灭菌与辐照服务商以及专家咨询服务商。 我们能满足您从产品设计到商品化的所有需求,确保您的产品和工艺安全无虞。